Voortman CNC beam cambering features a rigid steel Cframe, a horizontal Cylinder pusher and memory settings. This allows for consistent output on each project. The V2000 is easily operated by the touchscreen operator panel.

Voortman CNC Beam Cambering utilizes a rigid, stainless steel C frame, horizontal pusher, and memory settings to ensure reliable output for all types of projects. It has an intuitive touchscreen operator panel, making it easy to use the V2000.

Gulf States Saw & Machine Co. uses a rigid C frame made of steel, a horizontal pusher, as well memory settings, to produce Voortman CBN Cambering. This ensures reliable output on all projects. Voortman CNC Beam Cambering uses a touchscreen operator panel.

Gulf States Saw & Machine Co. uses a steel C-frame and horizontal pusher as well as memory settings to produce Voortman CNC Beam Cambering. This guarantees reliable output on all projects. Voortman CNC Beam Cambering includes a touchscreen operator panel, which makes it easy to use the V2000.

Gulf States Saw & Machine Co. offers the assurance of robotic profiling and coping that are unmatched in the industry. Our high definition plasma technology system, capable of cutting through a wide array of metal profiles, not just structural steel, but also other metal pieces, is able to do so with a high degree of precision.

If there are any concerns about our Robotic Coping and Profiling machine's standards, we can confirm that it has passed all of the essential fabrication tests. These include hardness, surface, beam flange hole quality and bolt hole sizing. We have, as usual, made the Voortman CNC coping and profiling available from our stocking.

BENEFITS: Smart cambering, Automatic positioning, Accurate, Automated, Hydraulic Cylinder with Pusher, PLC control and Remote control for mobility. You can also combine cambering with other Voortman machine.

Gulf States Saw & Machine Co. uses a C-frame made of steel and a horizontal pusher. Memory settings are used to produce Voortman CNC Beam Cambering. This assures reliable output on all projects. Voortman CNC Beam Cambering has a touchscreen operator panel. This makes it easy for you to use your V2000.

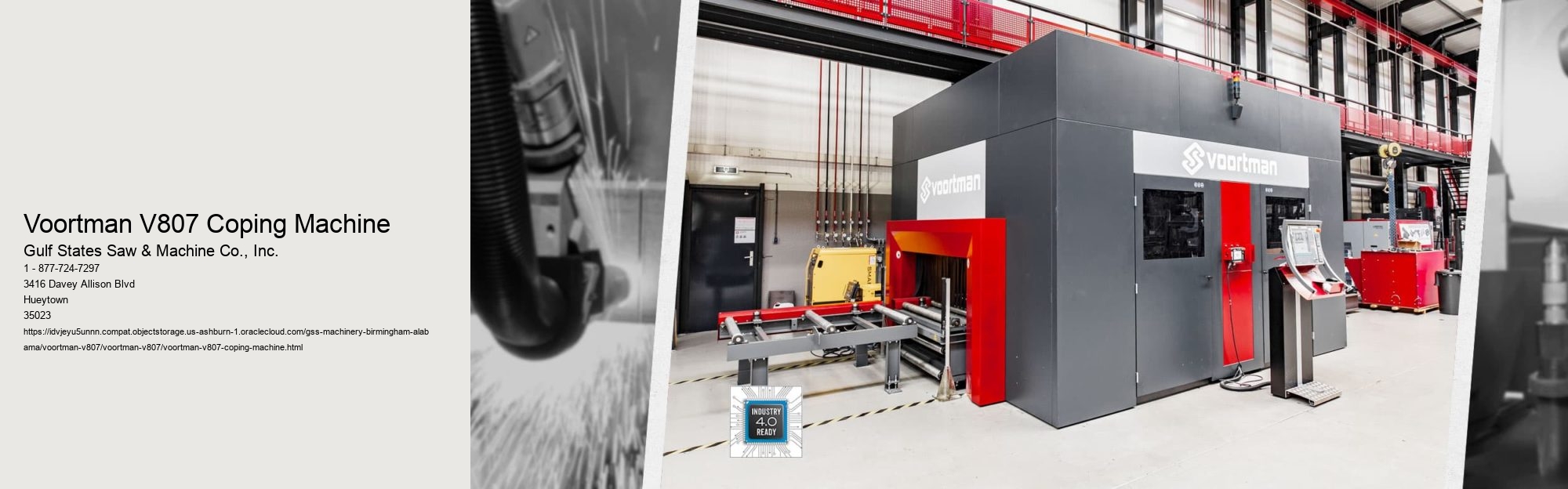

Voortman Metal Machinery is pleased to announce the VoortmanV807 robotically thermal profile machine. This machine is capable of plasma and oxygen cutting with greater throughput than other robotic processing machines. After the V808 profile processor's success, the V807 represents years of experience and research. It is the result of extensive research and development that drastically reduced the machine’s footprint and enhanced its already exceptional capability and performance.

Cost-effective thermal or plasma robotic profiling machines

Voortman Steel Machinery is proud to announce the new Voortman V807 robotic thermal profile processing machine - capable of plasma and oxy-fuel cutting with more throughput than other robotic profile processing machines in the market! After the widely successful V808 profile processor, the V807 is the result of years of experience, research and development to drastically reduce the machine’s footprint and enhance the already superior capability and performance.

Voortman V2000 Beam Cambering & Straightening Machine. The result is consistent and reliable every time.

Voortman CNC Beam Cambering uses a steel C-frame and a horizontal pusher. It also has memory settings that ensure reliable output for all projects. The V2000 has a touchscreen operator panel that is easy to use and features simple functionality.

The V807 delivers a quicker return-on-investment and lower costs than traditional solutions for drilling, milling or sawing. With the V807 all of these processes can be done in one step.

Coped joints are preferred by trim carpenters and other professionals because they open up less than miters during dry weather. Copped joints are better suited for corners that are not square than miters. Miters require a corner of 90 degrees to ensure a perfect fit.

Step 2: Measure the Baseboard and Mark the Place to Cope. We will first coping the board (on the right) and then measure the length of the wall to make the straight cut at the opposite end. This is done by making sure that your board is at least 2 inches longer than the actual wall.

Structural Fab Machinery, Fabrication Machinery. To describe the process of cutting reliefs in parts so that they can be properly fitted, we use the common term "Coping" in the metalworking industry.

The terms drag and cope are used in foundry work to refer to the top and bottom of a two-part casting flask that is used for sand casting.